Silicone Rubber Recycling

Recycled Skin Process Flow

| 1. Different Colors of silicone rubber burr is set aside and used as recycled material. |

|

|

2. Recycle silicone rubber is manually cut into small flakes Additional manpower required for Recycled Skin as compared with ordinary skin |

|

| 3. Disperse flakes of recycled silicone rubber evenly throughout a piece of raw silicone rubber. |

|

| 4. Material mixing in progress |

|

| 5. Material mixing completed |

|

| 6. Cut mixed material into required size to fit into master tool |

|

| 7. Place the mixed material into the master tool |

|

| 8. Compression molding completed |

|

| 9. De-Molded after compression molding | 10. Intensive manual de-burring |

| Additional manpower and wastage as compared to ordinary skins | |

|

|

| 11. Different amount (%) of recycled silicone rubber flakes – unique pattern on each skin |

|

Different amount (%) of Recycled Silicone Rubber

| Material Thickness: 1.0mm | Material Thickness: 1.5mm | |

|

|

|

| Composition: 25% recycled silicone 75% raw silicone Result: out of shape | Composition: 15% recycled silicone 85% raw silicone Result: In good shape | Composition: 25% recycled silicone 75% raw silicone Result: In good shape |

Important Notes

|

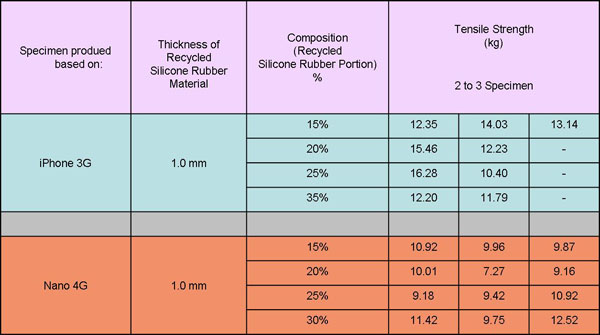

Recycled Skin – Tensile Strength Test

|

Test Procedure:

|

Recycled skin – Tensile Strength Test

Photo images: Tensile Strength Tests in Progress

|

|

|

|

Recycled skin – Tensile Strength Test

Photo images: Tensile Strength Tests in Progress

|

|

|

|

Recycled skin – Tensile Strength Test Report

Conclusion

Recycled skins exhibit a relatively weaker tensile strength. The higher percentage of recycled silicone rubber content, the more vulnerable it is to tear.

Production of Recycled Skins will cause:

- Higher wastage

- Higher production cost